GTEK Permanent Magnetic Chuck for Surface Grinder

Keywords: Permanent Magnetic Chuck, Magnetic Workholding, Fine Pole Magnetic Chuck, Magnetic Chuck for Surface Grinder.

X41 Magnetic Chucks for Surface Grinder

GTEK X41 series Permanent Magnetic Chuck is an ideal choice for general surface grinding and light milling EDM applications. It adopts high quality neodymium magnets as the power core, which provides a clamping force of 120N/cm², make the grinding process safe and convenient.

For small and thin workpieces, we have 0.5+1mm ultra fine pole pitch version, which maintains a low magnetic penetration to the work piece. This allows for superior holding of thinner workpieces.

And for medium and large parts, we prepared 0.5+1.5mm ordinary fine pole pitch and 1+3mm coarse pole pitch.

GTEK offers a wide active work area range from 70mm*160mm to 400mm*600mm, can be fitted on most sizes of surface grinders.

Features of Permanent Magnetic Chuck

As we know the biggest difference between a permanent and an electromagnetic chuck is the way they generate the magnetic field. And the independence from electrical power of permanent magnet chucks brings them below advantages:

- Less power consumption;

- Easy installation and transfer from one to another;

- Uniform magnetic field, and will not cause danger due to the sudden power failure;

- Will not generate heat, which can cause deform of some precision workpiece.

However, permanent magnetic chucks also have below disadvantages:

- Due to their mechanical magnetic switch control, not efficient for automated work;

- Due to the nature of the magnet, it is not suitable for processing parts with a temperature higher than 80°C.

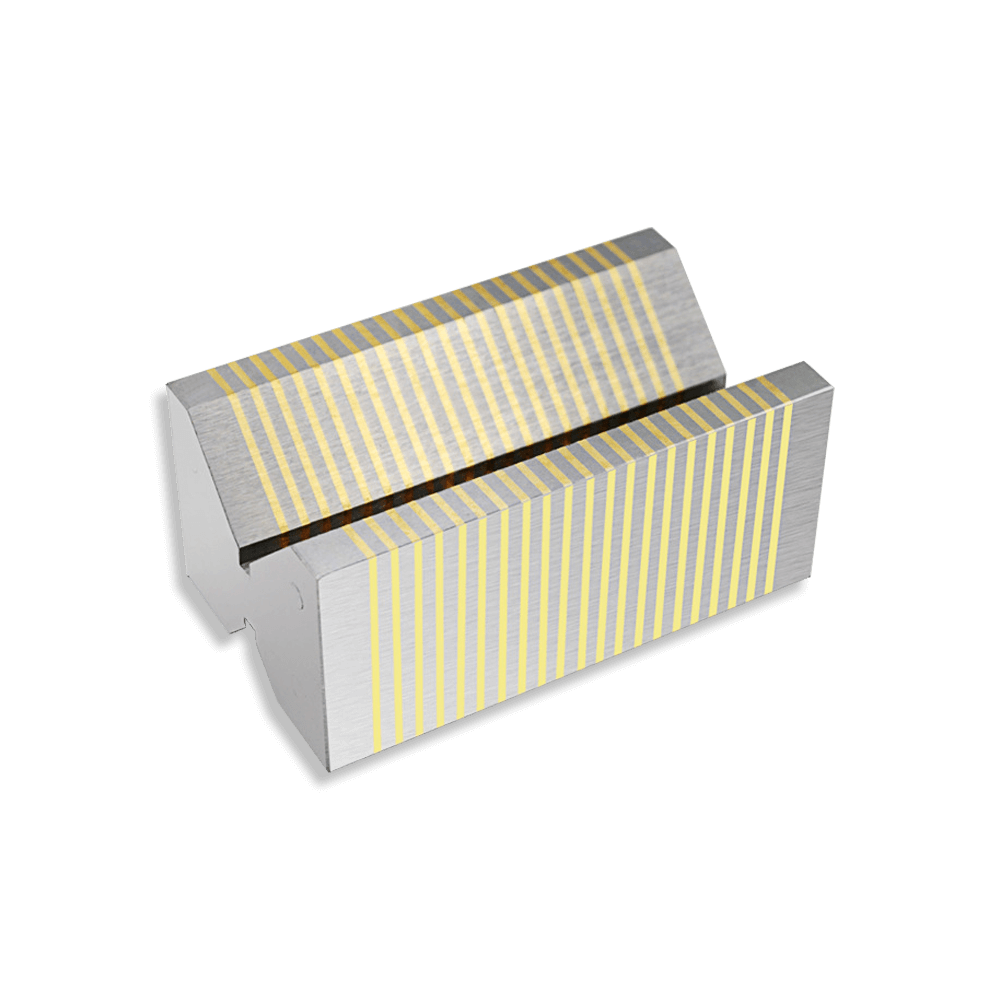

Magnetic Transfer Blocks for Surface Grinding Applications

GTEK provides Magnetic Transfer Parallels and V-Blocks. These accessories can be used with our permanent magnetic chucks for transfering the magnetic force in some specific surface grinding applications, for example: grinding cylinders, rounds, parts with high and low surface like stairs...

GTEK can do the customization on the pole pitchs and dimensions. For V-blocks we can also frabicate according to your specific drawings if you have.

Magnetic Sine Plates for Grinding Angles

GTEK develops X42 and X43 series magnetic sine plates based on the X41 permanent magnetic chucks. Which means, they have the similar characteristic as the X41, and can be used for grinding angle surface.

Magnetic Sine Plates are widely used in Grinding, Palletizing, Sinker EDM, Hard Milling and Inspection. With same optional pole pitchs as the X41 chuck series.

Interested in Our Magnetic Chuck?

Find avaliable models and get a quote today!