How To Make A Neodymium Magnet

In daily production, the price of NdFeB magnets varies from one hundred to several hundred, depending on the processing technology. Generally, NdFeB magnets are commonly used in three production processes, namely sintering process, bonding process and injection molding process.

Sintered NdFeB Magnets

The sintered NdFeB magnet process is to pulverize the magnetic material into a powder by air flow grinding, and then put it into a smelting furnace to smelt it into a specified overall material. The coercive force of NdFeB magnets produced by this process is very high, and it has a magnetic energy product more than ten times that of ordinary ferrite magnets.

The price of NdFeB produced by sintering process has a certain standard, and it will not be much different. After it is formed, it can be cut into products of different shapes as needed.

The chemical activity of Sintered NdFeB Magnet's surface is relatively high, so it must be electroplated on the surface layer. The commonly used is zinc plating and nickel plating.

Bonded NdFeB Magnets

The price of Bonded NdFeB Magnets is higher than that of sintered NdFeB magnets, mainly because it is integrally formed, and it is completed in one operation without any other cutting operations.

It is achieved by combining NdFeB powder and some other The materials are mixed together and made by compression, extrusion or injection molding.

Injection Molding NdFeB Magnets

The injection molding NdFeB magnet technology is the most demanding of all processes. The NdFeB magnet produced by this technology has the highest price. It requires extremely fine and precise molds.

The NdFeB powder is put into it to make a complex-shaped finished product. Most of the finished products are very thin.

Polishing Methods

The surface of the sintered NdFeB permanent magnet generally requires smoothness and a certain precision. The surface of the magnet delivered by the blank needs to be polished.

- Commonly used grinding and processing methods for square NdFeB permanent magnet alloys are: flat grinding, both end face grinding, inner circle grinding, and outer circle grinding.

- Cylindrical magnets often use coreless grinding and double-end flat grinding.

- The arc magnets, fan-shaped magnets and heterosexual magnets use multi-station grinders.

Tolerance Control

To see whether a magnet product is qualified, not only does it need to meet the performance standards, but the dimensional tolerance of the magnet is worth controlling and also directly affects its product performance and application.

The accurate guarantee of the magnet size tolerance value also directly depends on the factory's product processing strength. GTEK adopts full-automatic visual inspection and has a professional automated R & D team dedicated to the automated development of inspection equipment to improve efficiency and quality. At present, GTEK's tolerance control range for conventional NdFeB magnet products is shown in the following figure:

| Shapes | Tolerance Control Range (Square\Disc\Ring) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dimension | Outer Diameter | Inside Diameter | Length | Width | Thickness | Flatness | Parallelism | Verticality | Roundness | Concentricity |

| ≤5mm | 0.03 | 0.05 | 0.04 | 0.04 | 0.04 | 0.02 | 0.03 | 0.03 | 0.02 | 0.04 |

| 5<AND≤30mm | 0.05 | 0.06 | 0.06 | 0.06 | 0.06 | 0.02 | 0.04 | 0.05 | 0.02 | 0.05 |

| 30<AND≤70mm | 0.08 | 0.1 | 0.08 | 0.08 | 0.08 | 0.04 | 0.06 | 0.1 | 0.03 | 0.1 |

| 70<AND≤120mm | 0.08 | 0.15 | 0.1 | 0.1 | 0.1 | 0.04 | 0.08 | 0.15 | 0.05 | 0.15 |

| 120-200mm | 0.15 | 0.18 | 0.15 | 0.15 | 0.15 | 0.06 | 0.12 | 0.3 | 0.06 | 0.3 |

Magnet Processing Machinery

Magnet machining division:

- Punching processing:

The round bar and square bar magnets are punched and processed into cylindrical or square tube magnets; - Cutting processing:

The cylindrical and square column magnets are cut into slices or square slices by a slicer; - Shape processing:

Processing round and square-shaped magnets into tile-shaped, fan-shaped, groove-shaped or special-shaped magnets with other complex shapes;

The processing methods of different-shaped slices are: Grinding and slicing, laser slicing and EDM slicing;

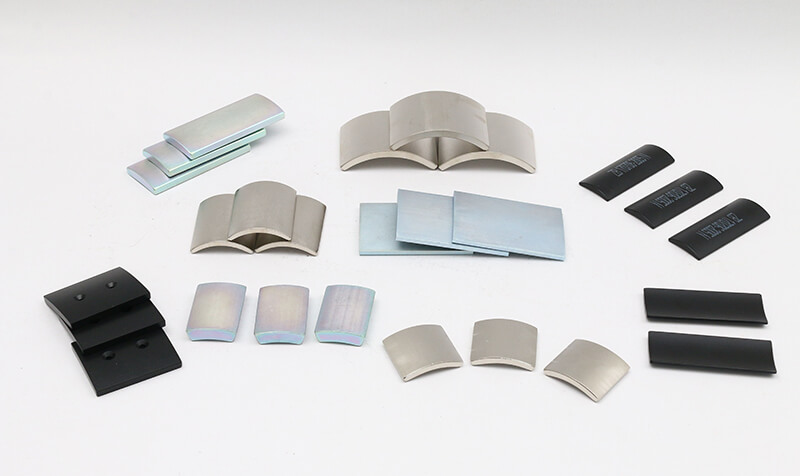

In practical applications, the shape and performance of NdFeB permanent magnets are various, for example: Discs, cylinders, rings, cylinders (with inner holes); squares, squares; fan-shaped, tile-shaped, trapezoidal, grooved, polygonal polygons and irregularities.

The size, performance, tolerance value, and magnetization method of each permanent magnet with different shapes are different.