Electromagnetic Vibrating Feeder

GTEK Electromagnetic Vibrating Feeder

Introduction

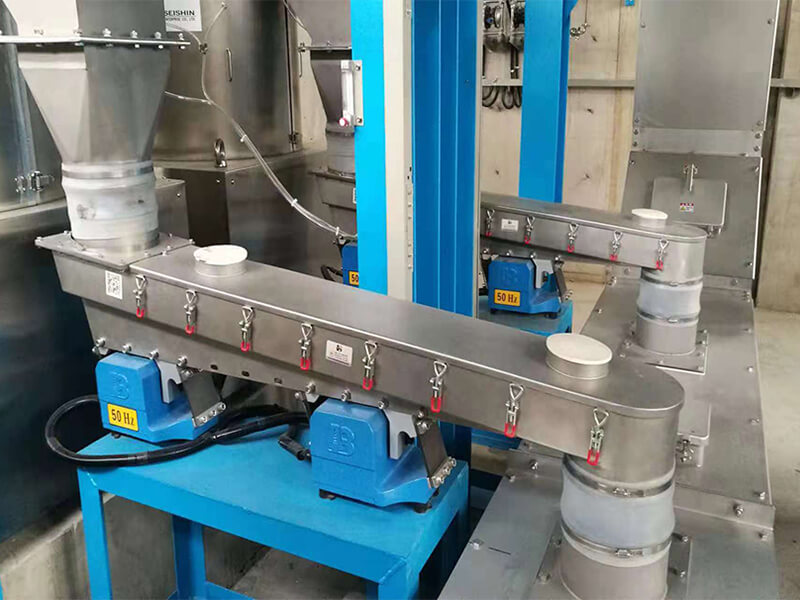

Electromagnetic vibrating feeder is used to uniformly or quantitatively supply materials from storage bins or other storage equipment to receiving equipment. It is a necessary equipment for automatic flow operation. Used for quantitative or continuous supply of block, granular or powder materials. It is widely used in mining, metallurgy, coal, electric power, chemical, food, glass, refractory and other industries.

The electromagnetic vibrating feeder can be divided into suspended type and desktop type according to the installation method. It has simple structure, convenient operation, no need for lubrication, and low power consumption.

We Provide Various Types of Electromagnetic Vibrating Feeder

GTEK provides three types of electromagnetic vibrating feeder: • FZW™ series mirco electromagnetic vibrating feeder, FZL™ series light electromagnetic vibrating feeder, FZH™ series high efficiency electromagnetic separator.

FZW Series Micro Electromagnetic Vibrating Feeder

FZW electromagnetic vibrating feeder is a miniature electromagnetic drive unit, with good control linearity and super recovery of special leaf springs, which can realize high-precision weighing and conveying.

Features:

- Reduced interference force: through reasonable configuration, the vibration force of the whole machine on the support base is greatly reduced.

- Various conveying carriers: different types of tanks can be configured to meet different needs.

- Good linearity: The leaf spring with reliable restoring ability makes the whole machine have good linearity and can meet high precision requirements.

- Low power consumption: The driver is close to the resonance range so that a lower current can be used with sufficient capacity.

FZL Series Light Type Electromagnetic Vibrating Feeder

FZL series electromagnetic vibrating feeder is a new type equipment that uses special leaf springs. Compare with traditional vibrating feeders, it has compact structure, light weight, stable operation, low noise, low energy consumption, and convenient installation and maintenance. The driving body is sealed and can be washed by water directly.

The conveying capacity of FZL light type electromagnetic vibrating feeder ranges from 0.5 tons per hour to 10 tons per hour.

The protection level of the whole machine can reach IP56.

Features:

Transmission frame

High-strength cast aluminum alloy

Advantages: easy installation, light weight, and a variety of troughs can be installed

Leaf spring group

Special leaf spring

Advantages: ultra-high fatigue strength, maintenance-free continuous work

Frame

High-strength cast iron

Advantages: compact structure, waterproof and dustproof

Electromagnet, Coil

The magnetic core and coil are placed in epoxy resin

Advantages: resistance to water vapor and dust, stable operation in harsh environments

Sealant block

Flexible silicone

Advantages: dustproof, waterproof, effective supplement of leaf spring group

Damping block

Flexible rubber and metal connectors are integrated

Advantages: special customization, good flexibility, long working life, convenient loading and unloading

Incoming cable

Simple electrical connection, handover protection

Advantages: easy installation, reliable operation

FZH Series High Efficiency Electromagnetic Vibrating Feeder

The FZH series high-efficiency electromagnetic vibrating feeder utilizes optimized structural design and takes into account the pressure requirements of the equipment under different working environments. The key components of the drive are specially treated and can be used in harsh working environments.

Compared with the traditional feeder equipment, it has the advantages of compact and simple structure, light weight, stable operation, low noise, low energy consumption, convenient installation and maintenance, and full-body seal driving.

The conveying capacity of FZH high-efficiency electromagnetic vibrating feeder ranges from 20 tons per hour to 500 tons per hour.

Features

Top cover, eye bolt

Glass fiber reinforced plastic, easy to install, rubber seal, dustproof and waterproof.

Advantages: reliable operation and safe operation.

Auxiliary weight block

Used to match the working weight of work equipment.

Advantages: interchangeable, suitable for different work units, reducing inventory and purchasing costs.

Spring leaf group (imported from Germany)

Special surface treatment.

Advantages: anti-wear, reduce maintenance costs, and can continually work at full power.

Electromagnet

The magnetic core and coil are cast in epoxy resin, resistant to moisture and dust, and fully sealed.

Advantages: It can operate reliably in harsh environments, with explosion-proof and wet room options available.

Incoming cable sealing, pre-configured cable

The electrical wiring is simple and spliced protection.

Advantages: easy installation and reliable operation.

Frame

The high-foot design facilitates the installation of long stress bolts, and the equipment can be easily installed in the required position. The multi-column structure can withstand high stress.

Optional Troughs

In order to meet the requirements of the food, pharmaceutical, and chemical industries, the trough has a variety of stainless steel surface treatment methods; the interior of the trough can be coated with special coatings, including: Teflon, polyurethane, rubber, etc. The selection of the trough needs to be comprehensively evaluated and calculated according to the nature of the material, the purpose of conveying, and the conveying volume.

For any selection and modification of the trough, please contact GTEK experts.

| Optional Surface Treatment | |

|---|---|

| Stainless Steel Mirror Polishing | PTFE/PFA/PVDF Coating |

| Stainless Steel Sandblasting | UPE/Polyurethane Lining |

| Carbon Steel/ Static Plastic-absorbing | Hardox/Overlay Welding Lining |

How Does an Electromagnetic Vibrating Feeder Work?

The electromagnetic vibrating feeder is mainly composed of two parts: a trough and an electromagnetic vibrator.

The electromagnetic vibrator is composed of a shell, an iron core, and a coil winding. The unidirectional alternating current passes through the rectifier to form a pulse current. When the power is turned on, there is a current in the coil winding, which generates a pulse electromagnetic attraction between the iron core and the armature, and the conveying trough moves backward under the action of the pulse electromagnetic attraction. The leaf spring deforms and stores a certain potential energy;

And when there is no current passing through the coil, the electromagnetic attraction disappears, the potential energy in the leaf spring is released, the armature and the iron core away from each other, and the conveying trough moves forward. By analogy, the conveying trough reciprocates at a certain frequency of AC power, which can accurately control the conveying of materials.

1. Conveying Trough 2. Connection Fork 3. Armature 4. Iron Core 5. Leaf Spring 6. Shell 7. Shock Absorber or Rubber Base Feet

Send Us a Message

NEED MAGNETS?

WE ARE HERE TO HELP!

Welcome to contact us by submitting the contact form or write to us directly through the contact info below:

For more information about any of our services, don’t hesitate to get in touch. Our team are always happy to help provide information and suggestion.

MAGNETIC FORCE BY GTEK™