Magnetic Chuck

GTEK Magnetic Chuck

What for?

Magnetic chucks aka magnetic tables are widely used as magnetic fixtures / workholding system in machining fields, such as machinery factories, mold factories, etc.

Magnetic Workholding System can greatly improve the clamping efficiency of magnetic steel materials.

GTEK MAGNET as a professional magnetic table manufacturer with more than 20 years' experience of supporting metal work industries, offers various kinds of magnetic tables, such as Permanent Magnetic Chucks & Electro-permanent Magnetic Chucks (EEPM Chucks), Fine Pole Magnetic Chucks, etc.

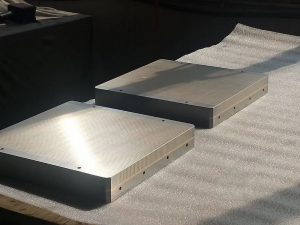

PMSC Series Permanent Magnetic Chuck For CNC Machine

Our permanent magnetic chuck is based on the high-performance rare earth material NdFeB (Grade > N40) as the core.

By manually turning the chuck handle, changing the magnetic system internally to achieve the holding or release of the processed workpiece.

GTEK PMSC Series Permanent Magnetic Chuck is our most popular model of magnetic tables. Suitable for most machine parts processing occasions.

Applications:

Permanent Magnetic Table is suitable for metal cutting. It is generally applied to CNC machining centers, CNC engraving and milling machines, grinding machines and other mechanical processing equipment.

Features:

- Magnetic force produced by high-performance rare-earth materials, no time limit, no power consumption, no heat, environmental friendly and safety, practical and easy to operate.

- The suction force is super strong, and the magnetic force can be superimposed. It increases according to the contact area of the workpiece and chuck. Can be used for high-intensity uninterrupted iron cutting and drilling work.

- The PMSC series has high rigidity and strong stability. It will not generate heat and deform during use, and can achieve precision processing.

- Simple mechanical switch, no power supply, to avoid the magnetic force disappeared due to sudden power failure, the risk of workpiece falling off.

- Can easily and quickly replace the clamping workpiece, significantly improving work efficiency by 80%.

| Model | A (mm) | B (mm) | H (mm) | Block Qty | Magnetic force per block (kgf) | Total suction (kn) |

|---|---|---|---|---|---|---|

| PMSC-2040 | 200 | 400 | 70/90 | 136 | 40 | 2856 |

| PMSC-3030 | 300 | 300 | 70/90 | 132 | 40 | 2772 |

| PMSC-3040 | 300 | 400 | 70/90 | 176 | 40 | 3696 |

| PMSC-3050 | 300 | 500 | 90 | 225 | 40 | 4725 |

| PMSC-3060 | 300 | 600 | 90 | 275 | 40 | 5775 |

| PMSC-4040 | 400 | 400 | 90 | 240 | 40 | 5040 |

| PMSC-4050 | 400 | 500 | 90 | 300 | 40 | 6300 |

| PMSC-4060 | 400 | 600 | 90 | 375 | 40 | 7875 |

| PMSC-4080 | 400 | 800 | 90 | 480 | 40 | 10080 |

| PMSC-5050 | 500 | 500 | 90 | 400 | 40 | 8400 |

| PMSC-5060 | 500 | 600 | 90 | 475 | 40 | 13230 |

| PMSC-5080 | 500 | 800 | 90 | 630 | 40 | 9975 |

| PMSC-6080 | 600 | 800 | 90 | 630 | 40 | 16632 |

| PMSC-50100 | 500 | 1000 | 90 | 800 | 40 | 16800 |

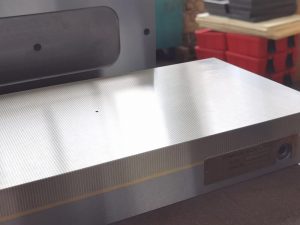

X41 Series Fine Pole Precision Permanent Magnetic Chuck for Surface Grinder

GTEK™ X41 Series Fine Pole Precision Permanent Magnetic Table is applicable to a variety grinding machines, EDM, line cutting, tapping machines, bench drill and other processing.

The pole pitchs are optional with Fine Pole Pitch (0.5+1.5mm) or Normal Pole Pitch (1+3mm) or Ultra Fine Pole Pitch (1+0.5mm). With the help of the handle, you can easily control the holding and release of the objects.

In addition to rectangular fine pole magnetic table, we also provide round type, single/double sine type, vertical type, rotational type fine pole magnetic table for your choice. Customized service is also avaliable.

The standard clamping force of the X41 fine pole magnetic chuck can reach 120N/cm² , it is the best choice to use on surface grinders.

Accessories including: Switch Handle and Customizable Magnetic Transfer Block (Optional). Learn More...

| Model | L (mm) | B (mm) | H (mm) | T (mm) | Weight (kg) |

|---|---|---|---|---|---|

| X41-1010 | 100 | 100 | 48 | 20 | 3.8 |

| X41-10175 | 175 | 100 | 49 | 20 | 6.6 |

| X41-1515 | 150 | 150 | 51 | 20 | 8.5 |

| X41-1520 | 200 | 150 | 48 | 20 | 11 |

| X41-1525 | 250 | 150 | 51 | 20 | 14.1 |

| X41-1530 | 300 | 150 | 51 | 20 | 16.8 |

| X41-1535 | 350 | 150 | 51 | 20 | 19.6 |

| X41-1540 | 400 | 150 | 51 | 20 | 23.8 |

| X41-1545 | 450 | 150 | 51 | 20 | 26.5 |

| X41-2020 | 200 | 200 | 51 | 21 | 16 |

| X41-2025 | 250 | 200 | 51 | 21 | 18.5 |

| X41-2035 | 350 | 200 | 51 | 21 | 28.5 |

| X41-2040 | 400 | 200 | 51 | 21 | 31.8 |

| X41-2045 | 450 | 200 | 51 | 21 | 37.5 |

| X41-2550 | 500 | 250 | 56 | 23 | 57 |

| X41-3060 | 600 | 300 | 56 | 23 | 82 |

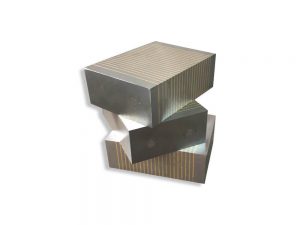

X42 Series Permanent Magnetic Sine Plate with Single Axis

GTEK™ X42 Series Permanent Magnetic Sine Chuck is designed for angled plane processing. When operating, the height of the pad required to process a specific angle can be obtained by calculation. Or you can just look through our operation manual for certain data.

The X42 Single Sine Magnetic Plate has the same pole pitchs optional as the X41 has: Fine Pole Pitch (0.5+1.5mm), Normal Pole Pitch (1+3mm), Ultra Fine Pole Pitch (1+0.5mm).

| Model | L (mm) | B (mm) | C (mm) | D (mm) | A (mm) | Magnetic Area (mm) | Tilting (°) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| X42-10175 | 175 | 100 | 86 | 75 | 225 | 175*100 | 0-60° | 11.5 |

| X42-1515 | 150 | 150 | 86 | 100 | 200 | 150*150 | 0-60° | 15 |

| X42-1530 | 300 | 150 | 86 | 100 | 350 | 300*150 | 0-60° | 32 |

| X42-12525 | 250 | 125 | 86 | 75 | 300 | 250*125 | 0-60° | 19.5 |

X43 Series Permanent Magnetic Sine Plate with Dual Axes

GTEK™ X43 Series Magnetic Sine Chuck has double axis to rotate, which makes it possible to perform dual-angled plane machining based on different axes.

The X43 Double Sine Magnetic Plate has the same pole pitch options as the X41: 0.5+1.5mm, 1+3mm and 1+0.5mm.

| Model | L1 (mm) | L2 (mm) | H (mm) | B1 (mm) | B2 (mm) | Magnetic Area (mm) | Tilting (°) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| X43-10175 | 100 | 175 | 110 | 75 | 100 | 175*100 | 0-45° | 12.6 |

| X43-1515 | 100 | 150 | 115 | 100 | 150 | 150*150 | 0-45° | 17 |

| X43-1530 | 150 | 300 | 115 | 100 | 150 | 300*150 | 0-45° | 34.5 |

| X43-12525 | 125 | 250 | 115 | 100 | 125 | 250*125 | 0-45° | 23 |

PMM Series Powerful Permanent Magnetic Chuck For Milling Machine

PMM series permanent magnetic table adopts dual-layer magnetic source design, which can generate a max. clamping force of 200N/cm². Especially suitable for fixing objects on milling machines.

And like all other permanent magnetic chucks, it can switch ON/OFF the magentic force by simply rotating the handle.

| Model | B (mm) | L (mm) | Effctive Length L1 (mm) | H (mm) | H1 (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| PMM-1525 | 150 | 250 | 199 | 56 | 23 | 17 |

| PMM-1530 | 150 | 300 | 259 | 56 | 23 | 20 |

| PMM-1535 | 150 | 350 | 304 | 56 | 23 | 24 |

| PMM-1545 | 150 | 450 | 409 | 60 | 23 | 31 |

| PMM-2030 | 200 | 300 | 259 | 60 | 23 | 29 |

| PMM-2040 | 200 | 400 | 349 | 59 | 23 | 37 |

| PMM-2045 | 200 | 450 | 409 | 60 | 23 | 41 |

| PMM-2050 | 200 | 500 | 459 | 59 | 23 | 46 |

| PMM-2060 | 200 | 600 | 559 | 59 | 23 | 55 |

| PMM-2530 | 250 | 300 | 259 | 60 | 23 | 35 |

| PMM-2535 | 250 | 350 | 304 | 60 | 23 | 41 |

| PMM-2540 | 250 | 400 | 349 | 60 | 23 | 47 |

| PMM-2545 | 250 | 450 | 409 | 60 | 23 | 52 |

| PMM-3030 | 300 | 300 | 259 | 60 | 23 | 39 |

| PMM-3040 | 300 | 400 | 349 | 60 | 23 | 52 |

| PMM-3050 | 300 | 500 | 459 | 60 | 23 | 65 |

| PMM-3060 | 300 | 600 | 559 | 62 | 23 | 80 |

| PMM-4040 | 400 | 400 | 349 | 60 | 23 | 71 |

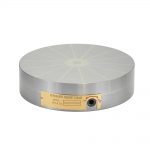

Rotary Magnetic Chuck For Lathe Machine | Magnetic Lathe Chuck

Lathe magnetic chuck can help to fix the workpiece on a lathe and makes it rotating about an axis of rotation to perform various operations, such as cutting, grinding, knurling, drilling, deformation, trimming and turning. Create an object symmetrical about this axis.

We provide three types magnetic chucks adapted for lathe workholding system:

X51 Seires Fine Pole Permanent Magnetic Chucks:

- Suitable for grinding on lathes;

- Optional pole pitch of 0.5+1.5m/ 1+3mm;

- Uniform magnetic force which can reach up to 120N/cm²;

- Specialized for small and thin workpiece;

- High precision.

X52 Seires Radial Pole Permanent Magnetic Chucks:

- Suitable for grinding on lathes and ring-shape workpieces;

- Radial pole pitch;

- Uniform magnetic force which can reach up to 180N/cm²;

- Adjustable magnetic force allows workpiece position calibration;

- Central through hole is available for the requests of workpiece centring and coolant supply;

- Can be equipped with t-slots for adjustable pole extension when turning or grinding ring-shaped workpieces.

| Model | D (mm) | H (mm) | K (mm) | C (mm) | Weight (kg) |

|---|---|---|---|---|---|

| X51-125 | 125 | 48 | 3 | 80 | 4.6 |

| X51-150 | 150 | 48 | 3 | 100 | 6.6 |

| X51-160 | 160 | 48 | 3 | 100 | 8.9 |

| X51-200 | 200 | 52 | 3 | 120 | 12.8 |

| X51-250 | 250 | 52 | 3 | 160 | 20 |

| X51-300 | 300 | 58 | 3 | 220 | 32 |

| X51-400 | 400 | 58 | 4 | 300 | 57 |

| X51-500 | 500 | 65 | 4 | 408 | 100 |

| Model | D1 (mm) | H (mm) | K (mm) | D2 (mm) | Weight (kg) |

|---|---|---|---|---|---|

| X52-160 | 160 | 58 | 3 | 120 | 10 |

| X52-200 | 200 | 58 | 3 | 160 | 14 |

| X52-250 | 250 | 58 | 3 | 200 | 23 |

| X52-300 | 300 | 60 | 3 | 250 | 43 |

| X52-350 | 350 | 60 | 4 | 250 | 59 |

| X52-400 | 400 | 70 | 4 | 200 | 78 |

| X52-500 | 500 | 70 | 4 | 200 | 148 |

RMM Seires Powerful Round Permanent Magnetic Chuck:

- Adapted for heavy cutting and carbon alloy processing;

- Pole pitch of 12mm steel and 3mm brass;

- Standard magnetic force can reach up to 180N/cm²;

- Magnetic field height: 10mm;

- Surface plate wearing limit: 5mm;

- Optional pole pitch of 15+4mm.

| Model | D1 (mm) | H (mm) | K (mm) | D2 (mm) | Weight (kg) |

|---|---|---|---|---|---|

| RMM160 | 160 | 56 | 3 | 125 | 8 |

| RMM200 | 200 | 56 | 3 | 150 | 13 |

| RMM250 | 250 | 56 | 3 | 200 | 20 |

| RMM300 | 300 | 56 | 3 | 250 | 29 |

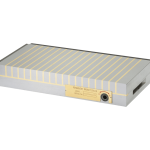

Electro Magnetic Chuck For Surface Grinding Machine

Electro Magnetic Chuck is the most common workholding device on surface grinder. Excellent steel properties, reducing precision changes during operation.

The whole body is waterproof treated to ensure long-term safety-using under the dipping of the cutting fluid.

The standard working voltage of GTEK™ electromagnetic chuck is 110V DC, connecting the transformer device of the surface grinding machine. The maximum suction power can reach more than 12kgf/cm².

Magnetic pole gap can be customized according to your specific requirements, to achieve both short or long object grinding.

| Model | A (mm) | B (mm) | H (mm) | Voltage (V) | Current (A) | Weight (kg) |

|---|---|---|---|---|---|---|

| X11-1540P | 150 | 400 | 85 | 110 | 0.5 | 40 |

| X11-2045P | 200 | 450 | 85 | 110 | 0.56 | 52 |

| X11-2050P | 200 | 500 | 85 | 110 | 0.6 | 58 |

| X11-2550P | 250 | 500 | 85 | 110 | 0.7 | 72 |

| X11-3060P | 300 | 600 | 85 | 110 | 0.98 | 104 |

| X11-4080P | 400 | 800 | 85 | 110 | 1.4 | 185 |

| X11-40100P | 400 | 1000 | 85 | 110 | 2.2 | 232 |

| X11-50100P | 500 | 1000 | 85 | 110 | 2.3 | 293 |

| X11-50120P | 500 | 1200 | 85 | 110 | 3.5 | 349 |

| X11-60150P | 600 | 1500 | 85 | 110 | 4.1 | 522 |

| X11-60200P | 600 | 2000 | 85 | 110 | 3.40*2 | 700 |

| X11-70150P | 700 | 1500 | 85 | 110 | 4.5 | 605 |

| X11-80200P | 800 | 2000 | 85 | 110 | 3.60*2 | 930 |

| X11-100150P | 1000 | 1500 | 85 | 110 | 3.80*2 | 805 |

| X11-100200P | 1000 | 2000 | 85 | 110 | 4.30*2 | 1050 |

| X11-150240P | 1500 | 2400 | 85 | 110 | 6.80*3 | 1930 |

| X11-150320P | 1500 | 3200 | 85 | 110 | 6.80*4 | 2570 |

| X11-150420P | 1500 | 4200 | 85 | 110 | 7.50*4 | 3380 |

| X11-200320P | 2000 | 3200 | 85 | 110 | 4.00*8 | 3350 |

| X11-200420P | 2000 | 4200 | 85 | 110 | 4.50*8 | 4400 |

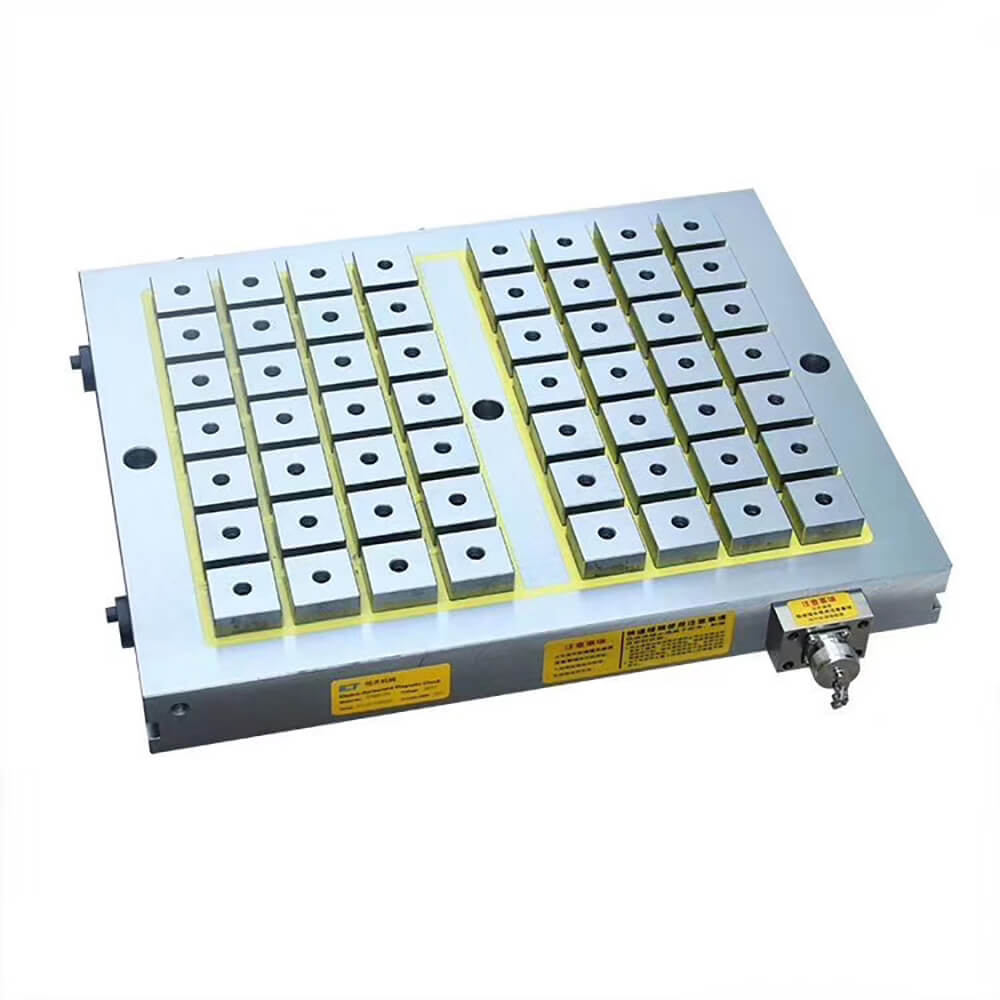

PTM Series Electro-Permanet Magnetic Chuck (EPM50 Chuck)

Electro-permanent magnetic chuck is a new type of fixture designed and developed combining the characteristics of electromagnetic and permanent magnets.

EPM50 Chuck is a new type of magnetic chucks that uses electric pulses "on and off" to control the magnetic force and requires less than 1 second. It is very safe and reliable during the processing of holding the workpiece.

Even if the power is cut off, the magnetic force will maintain indefinitely.

The EEPM chucks are widely used in CNC machining centers, milling machines, carving machines, etc.

Applications:

Field application: mechanical processing, mold processing, plastic processing, automobile manufacturing, shipbuilding, etc.

Machine tool application: machining center, injection molding machine, mold clamping machine, vertical lathe, milling machine, engraving machine and other machine tools.

Applicable processing methods: end milling, side drilling, round bar end milling, slotting, multi-part combination milling, plane machining, through-hole machining, cavity machining, boring, contour machining, three-position die machining, angle milling, and inverted Angle, horizontal milling, irregular workpiece processing, welding processing, etc.

Features:

Suitable for the holding of iron workpieces, unique magnetic circuit, reasonable parameters, uniform suction with strong rigidity, no thermal deformation, and high precision. Convenient operation, no power loss and demagnetization, safe and reliable use.

Accessories:

Accessories for EPM50 chucks including controller, connector and magnetic conductors.

* Standard pole size 50*50mm, larger pole size with 75*75mm can be an option.

| Model | A (mm) | B (mm) | C (mm) | Qty of poles | Weight (kg) |

|---|---|---|---|---|---|

| EPM50-205 | 470 | 230 | 68 | 18 | 55 |

| EPM50-206 | 620 | 230 | 68 | 24 | 75 |

| EPM50-208 | 770 | 230 | 68 | 30 | 90 |

| EPM50-209 | 920 | 230 | 68 | 36 | 110 |

| EMP50-210 | 1060 | 230 | 68 | 42 | 125 |

| EPM50-303 | 320 | 300 | 68 | 16 | 50 |

| EPM50-304 | 400 | 300 | 68 | 20 | 65 |

| EPM50-305 | 470 | 300 | 68 | 24 | 75 |

| EPM50-306 | 620 | 300 | 68 | 32 | 95 |

| EPM50-308 | 770 | 300 | 68 | 40 | 120 |

| EPM50-309 | 920 | 300 | 68 | 48 | 140 |

| EPM50-310 | 1060 | 300 | 68 | 56 | 165 |

| EPM50-404 | 400 | 410 | 68 | 30 | 88 |

| EPM50-405 | 470 | 410 | 68 | 36 | 100 |

| EPM50-406 | 620 | 410 | 68 | 48 | 130 |

| EPM50-408 | 770 | 410 | 68 | 60 | 160 |

| EPM50-409 | 920 | 410 | 68 | 72 | 195 |

| EPM50-410 | 1060 | 410 | 68 | 84 | 220 |

| EPM50-505 | 470 | 490 | 68 | 42 | 120 |

| EPM50-506 | 620 | 490 | 68 | 56 | 155 |

| EPM50-508 | 770 | 490 | 68 | 70 | 195 |

| EPM50-509 | 920 | 490 | 68 | 84 | 230 |

| EPM50-510 | 1060 | 490 | 68 | 98 | 265 |

| EPM50-606 | 620 | 600 | 68 | 72 | 190 |

| EPM50-608 | 770 | 600 | 68 | 90 | 235 |

| EPM50-609 | 920 | 600 | 68 | 108 | 280 |

| EPM50-610 | 1060 | 600 | 68 | 126 | 325 |

Send Us a Message

NEED MAGNETS?

WE ARE HERE TO HELP!

Welcome to contact us by submitting the contact form or write to us directly through the contact info below:

For more information about any of our services, don’t hesitate to get in touch. Our team are always happy to help provide information and suggestion.

MAGNETIC FORCE BY GTEK™