How Does a Belt Type High Gradient Magnetic Separator Work

The GTGP belt type high gradient magnetic separator is a new type of magnetic separator invented by our company. The design of the whole machine integrates physical mechanics, fluid mechanics and magnetic mechanics. It has super strong magnetic field, the highest magnetic field can reach 15000Gs.

The invention of the belt type high gradient magnetic separator can completely solve the high standard requirements for iron removal in various industries, and its cost is only one-tenth of the vertical ring type high gradient magnetic separator, with an ultra-high cost performance. It fundamentally solves the worldwide technical problems that traditional magnetic separators are easy to block and easy to agglomerate when processing small granular materials. It is also a revolutionary breakthrough in the field of high gradient magnetic separators.

The Structure Of Belt Type High Gradient Magnetic Separator

In order to better understand the working principle of the belt type high gradient magnetic separator, we first need to know its structural characteristics.

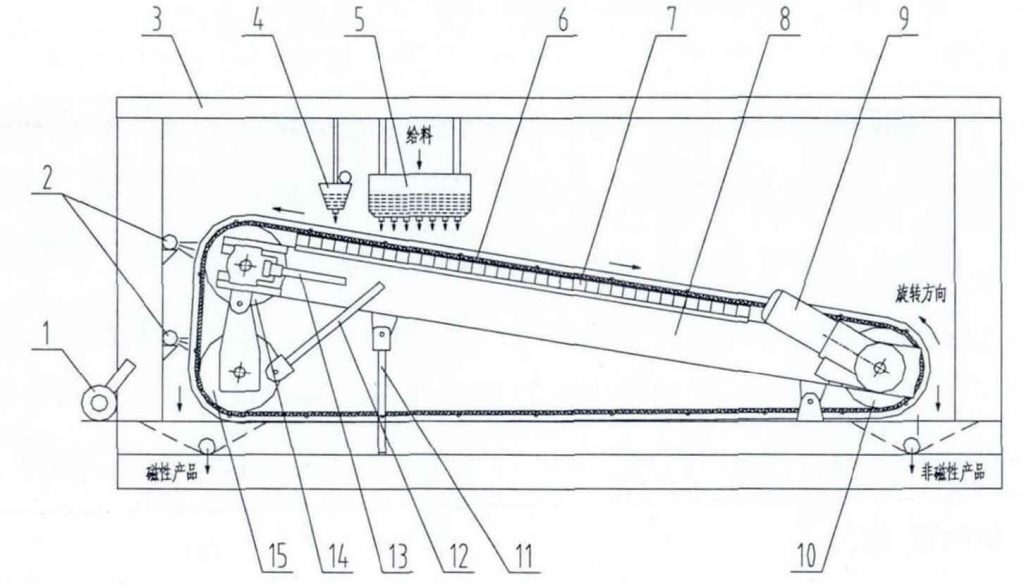

Belt type high gradient magnetic separator is mainly composed of flat magnetic system, U-belt, frame, feed tank, rinsing water tank, concentrate washing device, product collection tank, etc.

1. Magnetic System: The belt-type high-gradient magnetic separator adopts the extruded flat magnetic system. The magnetic system is composed of high-quality NdFeB magnetic material and magnetic poles. The magnetic poles are also used as magnetic conductive media, which can generate large magnetic field strength and gradient on the surface.

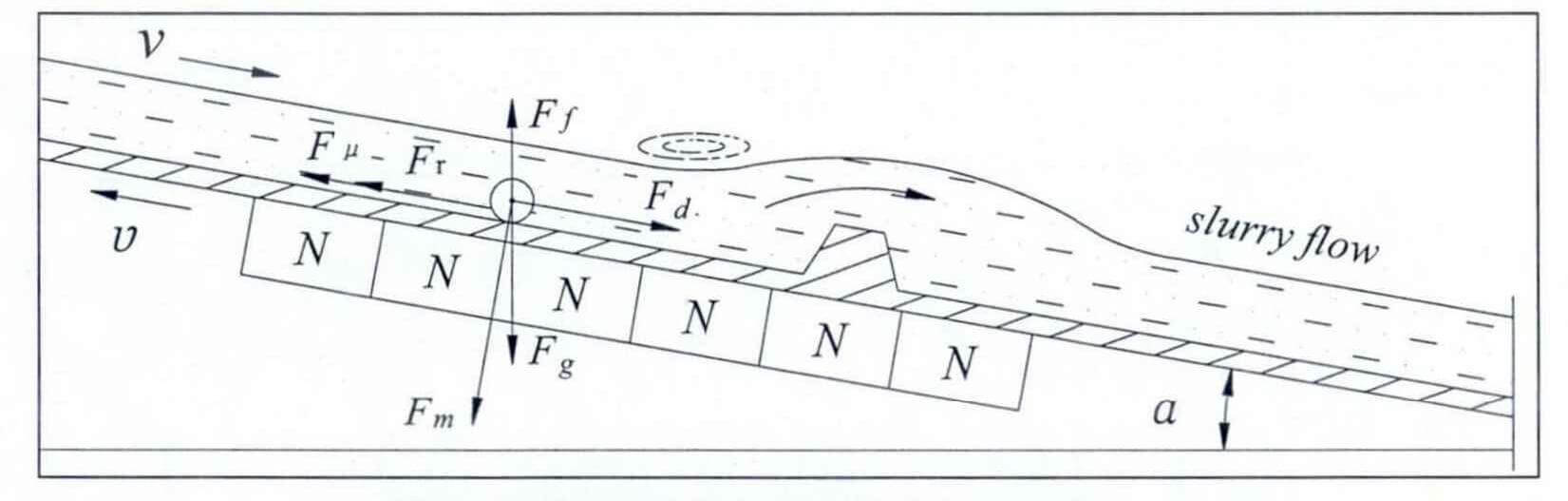

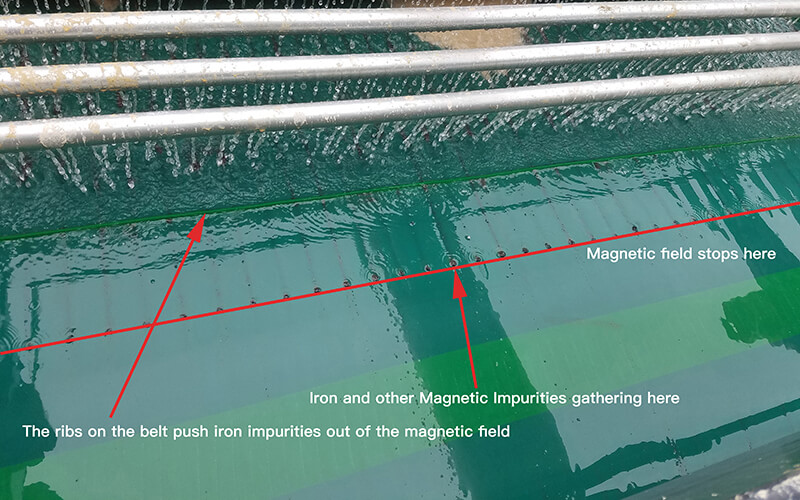

2. Belt: The belt consists of a main body surface of 1-2 mm thick, as well as ribs and rails. It plays a role of transporting ore pulp and is also a mineral separation area. The belt is made of high-quality PVC, which is resistant to abrasion and strong in tensile strength. The thickness of the belt is very small, which can ensure that the sorting area is within the depth of the magnetic field, the magnetic field strength and gradient on the belt surface will not drop too much. There are ribs on the surface of the belt every certain distance, which can trap the magnetic particles attracted by the magnetic force on the surface of the belt and carry them to the magnetic particle washing area; the ore pulp rolls over at the ribs to reduce mechanical inclusions.

3. Transmission System: The transmission system is composed of motor, reducer, active roller and passive roller. It is driven by the motor through the reducer to drive the active roller to rotate, and then drives the passive roller and belt to rotate, thereby bringing the magnetic products out of the ore pulp. The speed of the motor can be adjusted by the inverter according to the requirements.

4. Feed box, Rinsing sink and Magnetic Product Rinse Tube:

The feeding box is designed with two layers of bottoms, and the bottom of each layer is evenly distributed with round holes. After the slurry is fed to the feed box, it enters the lower layer of the feed box steadily after the buffering effect of the bottom of the upper layer, and then flows out from the holes evenly distributed at the bottom to achieve the purpose of uniform and stable feeding of the thin layer. The feed box can be moved longitudinally and laterally on the rack, so that it can be in different positions above the belt according to the nature of the material and the selection requirements. The magnetic product rinsing tube is located in the magnetic product rinsing area. There are evenly arranged small holes in the tube, which can spray high-speed water flow to rinse the magnetic product.

1. Main water pipe 2. Magnetic product flushing hose 3. Frame 4. Rinse sink 5. Feed Box 6. Belt 7. Magnetic system 8. Magnetic system support 9. Motor 10. Active roller 11. Tilt adjustment lever 12. Tighten screw 13. Tie rod 14/15. Passive roller

How Does a Belt Type High Gradient Magnetic Separator Work

After starting the equipment, turn on the magnetic product flushing hose. The ore pulp enters the feed box, flows evenly to the belt with a thickness of 1-2mm through the bottom hole, and flows counter to the belt.

Because the area near the magnetic pole (effective magnetic field area) has a strong magnetic field strength and gradient, when the slurry moves to the effective magnetic field area, the magnetic particles in it will be captured by the strong magnetic force and be tightly attached to the belt surface, then moving upwards along with the belt.

The weaker magnetic particles and some combination particles of non-magnetics and magnetics will still move downward with the pulp, but because there are ribs at a certain distance on the belt, when they moving to the ribs, they will be trapped by the ribs and move upward with the belt.

When these magnetic particles and weaker magnetic particles move up to the bottom of the rinsing tank, they will be washed again to reduce the content of non-magnetic particles in the cluster, and the magnetic particles are carried by the belt to the washing area and cleaned off by flushing water under a certain pressure.

Non-magnetic particles are not affected by magnetic force, and flow downward under the action of gravity and water flow, enter the non-magnetic product collection tank, and flow out from the ore discharge hole.