Magnetic Separator For Kaolin Clay

What Is Kaolin Clay?

Kaolin Clay is a combination of hydrated aluminosilicates composed of multiple minerals. The main mineral component is kaolin, and it also contains impurities such as quartz, smectite, illite and feldspar.

The appearance of kaolin ore is white, light gray and other colors, and its refractoriness is as high as 1700℃.

Pure kaolin has features of high whiteness, soft quality, easy to disperse and suspend in water, good plasticity, high cohesiveness, excellent electrical insulation performance, good acid solubility, low cation exchange capacity, and good fire resistance.

Kaolin has been widely used in dozens of industries such as papermaking, ceramics, rubber, chemicals, coatings, medicine and national defense.

Why Use a Magnetic Separator in Kaolin Industries?

Kaolin, as a chemical additive, can significantly improve the grade of the product and increase the added value of the product.

Whiteness is the main parameter of kaolin process performance. The higher the whiteness, the higher the purity and the higher the value of utilization. Natural kaolin often reduces its whiteness due to impurities. The harmful substances in kaolin can be divided into four categories: organic matter, iron, titanium-containing minerals, and dark minerals (such as biotite, chlorite, etc.). Among them, iron is often the main substance that affects the whiteness of kaolin.

Studies have shown that the iron in kaolin mostly exists in the form of hematite, pyrite, siderite, limonite, anatase, ilmenite and other mineral forms. It mainly exists in two forms:

- Most iron mainly exists in the form of colloidal limonite and is in a highly dispersed state;

- A small amount of iron minerals are nearly spherical, needle-like and irregular in shape, belonging to goethite and hematite mine.

Fe2+ is usually in the form of a film, wrapped on the surface of kaolin; Fe3+ exists as a free limonite. When Fe2O3 is contained in kaolin, it appears in color of rose red or brownish yellow; when Fe2+ is contained, it is light blue or light green.

Iron-bearing minerals will become Fe2O3 when calcined at high temperatures, causing the raw materials to turn yellow or brick red. Therefore, measures must be taken to remove iron before or during the calcination process to ensure the whiteness of kaolin.

The kaolin iron removal processes currently existing in the world can be summarized as follows: • magnetic separation • flotation • coagulation • flocculation • acid leaching • oxidation leaching • reduction leaching • microbial method, etc.

Magnetic Separators For Kaolin

Wet High Intensity Magnetic Separator/ Slurry High Intensity Magnetic Separator

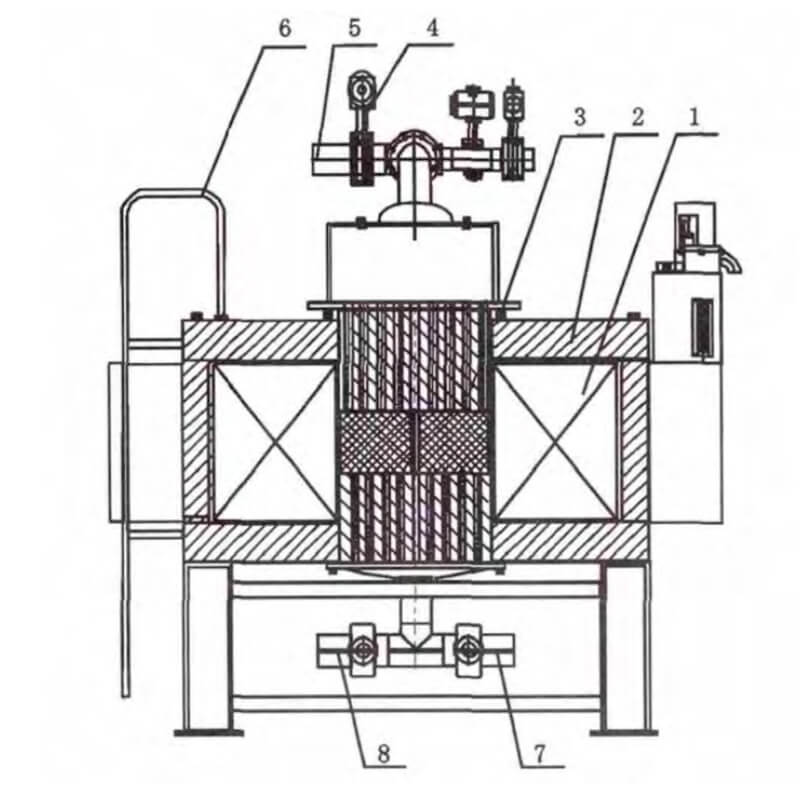

Wet High Intensity Magnetic Separator can be used to separate micron-sized materials. It is mainly composed of frame, oil-cooled excitation coil, magnetic system, separation medium, coil cooling system, flushing system, inlet and outlet system, control system, etc.

1. Excitation coil; 2. Magnetic system; 3. Separating medium; 4. Pneumatic valve; 5. Pulp pipe; 6. Escalator; 7. Slurry inlet pipe; 8. Magnetics discharge pipe.

Working Principle

In the armored coil, a certain amount of magnetically conductive stainless steel wool (or expanded metal) is placed.

After the coil is excited, the stainless steel wool is magnetized, its surface produces a highly uneven magnetic field, which is called the high gradient magnetic field.

When the slurry passes through the steel wool in the sorting tank, it will be adsorbed on the surface of the steel wool, while the non-magnetic materials pass through the magnetic field directly, and pass through the non-magnetic material discharge pipe.

When the weak magnetic material collected by the steel wool reaches a certain amount (determined by the process requirements), stop feeding the ore. Disconnect the excitation power supply and flush the magnetic material out. Then carry out the second operation, and repeat this cycle.

Plate Type High Gradient Magnetic Separator/ Belt Type High Gradient Magnetic Separator

GTEK belt type high gradient magnetic separator is mainly suitable for the separation of weak magnetic minerals with a particle size of less than 5mm.

It is suitable for iron removal of non-metallic minerals, such as: mica powder, quartz sand, potash feldspar, nepheline, fluorite, sillimanite, spodumene, kaolin, pyrrhotite, roasted ore, hematite, limonite, siderite, chromite, wolframite, tantalum-niobite, red mud, etc.

Working Principle

The plate type powerful permanent magnet is placed in the middle of the belt, from just below the feed inlet to the end pulley.

When feeding, the iron impurities in the product stream will be absorbed in the magnetic field area and transported upward through the belt, in the opposite direction of the non-magnetic material.

When the magnetic impurities are transported to the end of the magnetic field area, the magnetic impurities will stay at the end to gather into a cluster due to the action of the magnetic force, and then be pushed out of the magnetic field area by the rids on the belt. Eventually washed away by water and fall off the belt.

Interested In Our Magnetic Separator?

Check more of our magnetic separators and contact us today for a best magnetic solution!